Innovative Methods to Fillet Weld Inspection and Testing: Enhancing Weld Quality and Conformity Standards

In the realm of welding, the top quality and stability of fillet welds play an essential duty in guaranteeing the structural soundness and reliability of numerous commercial elements. With the constant drive for boosted efficiency and conformity with stringent standards, the exploration of innovative approaches to fillet weld evaluation and screening has actually come to be essential. As sectors advance, the conventional methods may no much longer suffice in fulfilling the needs of contemporary welding applications (Gauge Fillet Weld). By welcoming innovative innovations and methodologies, a new perspective of opportunities emerges in the world of weld top quality analysis and adherence to compliance standards.

Advanced Non-Destructive Testing Methods

Utilizing modern technologies, progressed non-destructive testing techniques play a vital duty in making sure the honesty and quality of fillet welds. These approaches, such as phased array ultrasonic screening (PAUT) and magnetic fragment testing (MPT), deal comprehensive understandings right into the weld's internal framework without creating any kind of damages to the product. PAUT, for circumstances, utilizes multiple ultrasonic elements to inspect the weld from various angles, providing a comprehensive visualization of potential problems like lack of blend or fractures.

Similarly, MPT is efficient in detecting surface-breaking problems by applying an electromagnetic field and iron bits to the weld location. This method is especially valuable for determining discontinuities that may jeopardize the weld's stamina. By utilizing these innovative non-destructive screening strategies, weld inspectors can accurately evaluate the quality of fillet welds, ensuring conformity with market criteria and laws. The capability to find imperfections beforehand not only improves weld top quality yet also avoids costly rework or failures in architectural honesty, underscoring the relevance of these cutting-edge screening approaches in welding examinations.

Robotics and Automation in Examination

The assimilation of robotics and automation has actually changed the assessment process for fillet welds, improving efficiency and precision in high quality assessment. Robotics provide specific control and repeatability in checking welds, ensuring trusted and regular outcomes. Automated systems can be programmed to adhere to specific assessment courses, guaranteeing thorough insurance coverage of welds and decreasing the risk of human mistake.

Robot inspection systems equipped with sophisticated sensors can discover and determine weld functions with high precision, giving thorough data for analysis. These systems can identify flaws such as fractures, lack of fusion, and porosity, enabling prompt restorative activities to be taken. In addition, robotics and automation allow for real-time data collection and evaluation, giving prompt feedback to drivers and assisting in fast decision-making procedures.

Furthermore, the usage of robotics and automation in fillet weld inspection boosts overall efficiency by lowering inspection times and enhancing examination throughput. By improving the assessment process, producers can make sure weld high quality and conformity requirements are met efficiently, ultimately causing set you back financial savings and improved product top quality.

Utilizing Artificial Knowledge for Evaluation

Man-made knowledge plays a crucial function in boosting the performance and precision of analysis in fillet weld assessment procedures. By utilizing the power of AI, examiners can enhance the evaluation of weld top quality and conformity requirements, leading to much more specific and reputable outcomes. AI algorithms can rapidly refine large amounts of data from weld assessments, detecting issues or variances that might be testing to relate to the nude eye. This sophisticated technology allows real-time tracking of weld top quality, enabling immediate corrective actions to be taken if any kind of issues are detected.

Furthermore, AI systems can gain from previous evaluation information, consistently boosting their ability to identify possible issues and inconsistencies in fillet welds. This adaptive discovering capability enhances the total quality control process, minimizing the likelihood of human error and ensuring that welds satisfy the needed standards. By incorporating artificial intelligence right into fillet weld evaluation, markets can attain higher degrees of performance, uniformity, and compliance in their examination techniques.

Portable Equipment for On-Site Inspection

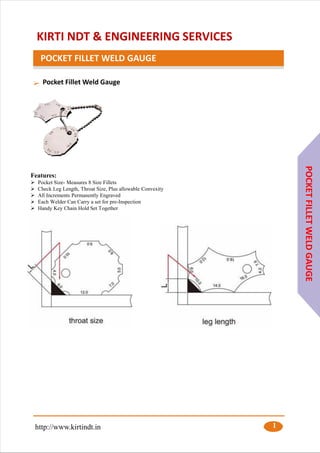

Enhancing area examination performance, the fostering of portable tools transforms on-site evaluation procedures for fillet welds. These tools supply flexibility and convenience, enabling examiners to perform detailed exams in different places, including tough or remote atmospheres. Portable devices such as ultrasonic screening gadgets, magnetic particle examination equipment, and digital radiography systems give real-time data and high-resolution imaging capacities, enabling fast decision-making and prompt responses on weld quality.

One considerable benefit of portable devices is their ability to improve inspection procedures, lowering downtime and improving general efficiency - Gauge Fillet Weld. Inspectors can quickly transfer these Read Full Report tools to different task sites, getting rid of the requirement for delivering heavy machinery or components to off-site facilities. In addition, the transportability of these tools advertises cost-effectiveness by minimizing transportation expenditures and accelerating assessment timelines

In addition, the use of mobile tools for on-site inspection promotes aggressive quality assurance steps, as examiners can quickly recognize and attend to any kind of prospective welding defects or inconsistencies. By including these ingenious modern technologies into on-site assessment techniques, welding professionals can make sure compliance with industry standards and enhance weld high quality, eventually resulting in enhanced structural honesty and safety and security in various welding applications.

Combination of Data Management Solution

Having actually maximized on-site examination processes through the usage of mobile tools, the following stage involves the smooth integration of information administration systems to additionally improve effectiveness and data evaluation capacities browse around this web-site in fillet weld examination and testing. By integrating data monitoring systems into the assessment process, organizations can improve information collection, storage, and evaluation. This integration permits real-time tracking of weld top quality, prompt recognition of problems, and punctual decision-making to fix any concerns that may occur throughout the examination procedure.

Information administration systems play an essential duty in streamlining inspection information, facilitating easy gain access to for authorized workers, and making sure information integrity and safety and security. Via the combination of these systems, inspectors can produce detailed reports, track historic information for pattern evaluation, and improve general process effectiveness. Furthermore, the integration of information management systems makes it possible for seamless communication in between various stakeholders associated with the examination process, cultivating collaboration and improving total quality control steps. Ultimately, the integration of information administration systems serves to raise the requirements of fillet weld evaluation and screening, ensuring conformity with market laws and improving weld quality.

Final Thought

In conclusion, cutting-edge strategies to fillet weld examination and screening have significantly improved weld top quality and compliance requirements. Advanced non-destructive screening approaches, robotics, automation, expert system, mobile tools, and information administration systems have actually reinvented the means weld assessments are carried out. By making use of these innovations, markets can make certain that welds meet the called for top quality criteria and regulations, eventually boosting general effectiveness and safety and security in welding processes.

Having actually maximized on-site examination processes via the application of portable devices, the following phase involves the smooth integration of data monitoring systems to additionally improve effectiveness and information evaluation capabilities in fillet weld inspection and screening. Eventually, the combination of information monitoring systems offers to elevate the criteria of fillet weld assessment and testing, guaranteeing compliance with market policies and improving weld top quality.